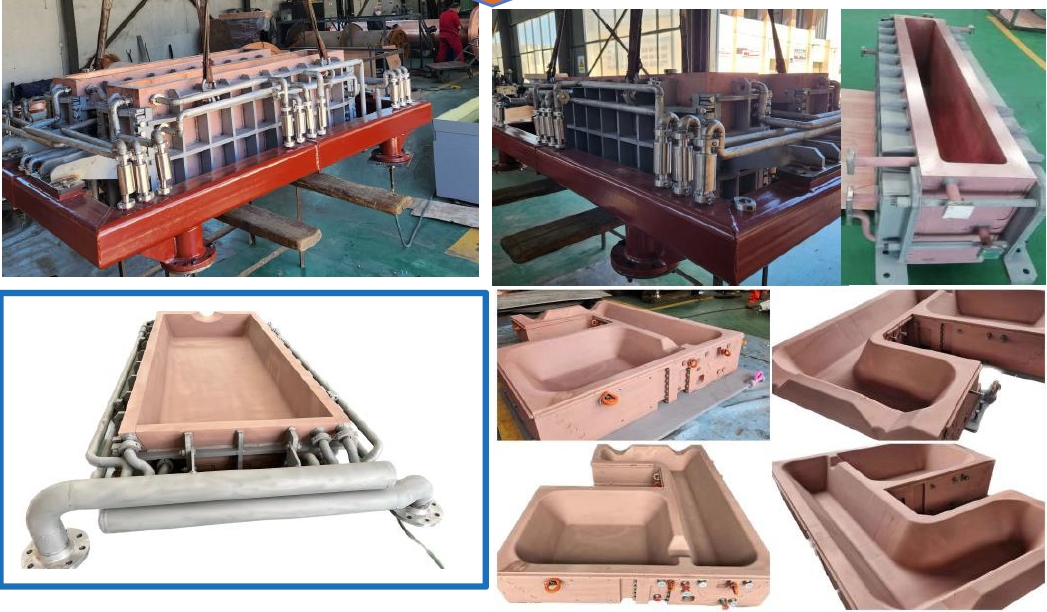

The copper mold of the EB furnace is the core component of the electron beam cooling bed melting furnace (EB furnace), mainly responsible for the final solidification and shaping of the metal melt.

Project |

Key content |

|---|---|

| Core function | Receiving the molten metal that has been melted by an electron beam and refined in a cold bed, it rapidly solidifies through forced water cooling to form high-purity ingots of specific shapes (such as round ingots, flat ingots, etc.) |

| Core material | Red copper and high thermal conductivity copper alloy chromium-zirconium copper (CuCrZr) have high-temperature strength, creep resistance and recrystallization temperature (about 690°C) far superior to those of ordinary copper materials |

| Characteristics of the working environment | High vacuum (typically 10⁻¹ to 10⁻³ Pa), direct or indirect bombardment by electron beams, contact with high-temperature molten metals (such as titanium, zirconium, etc.), and friction when ingots are pulled out |

| Key design/process | Precision water-cooled runner design, inner wall coating technology (such as hard chromium, nickel-cobalt alloy), and integrated connection design with the cooling bed |

| Core advantage | Separating the melting, refining and solidification processes can effectively remove high/low density inclusions, ensuring uniform ingot composition without segregation |

| Maintenance and repair | After wear, it can be repaired. Common methods include surfacing with welding wire of the same material, stress relief heat treatment, precision machining on CNC machine tools, and surface spraying of wear-resistant alloy coatings, etc |

From material selection to maintenance

Material is the key foundation: To ensure that the mold maintains its shape and strength at high temperatures and extends its service life, high-strength and high-conductivity copper alloys such as red copper, phosphor bronze, chromium-zirconium copper (CuCrZr) can be selected. It can still maintain good mechanical properties at high temperatures.

Maintenance enhances value: As an expensive component, the mold can restore its performance through professional repair techniques (such as surfacing to fill defects, heat treatment to relieve stress, and surface spraying of wear-resistant coatings) after wear, significantly extending its service life and meeting economic benefits