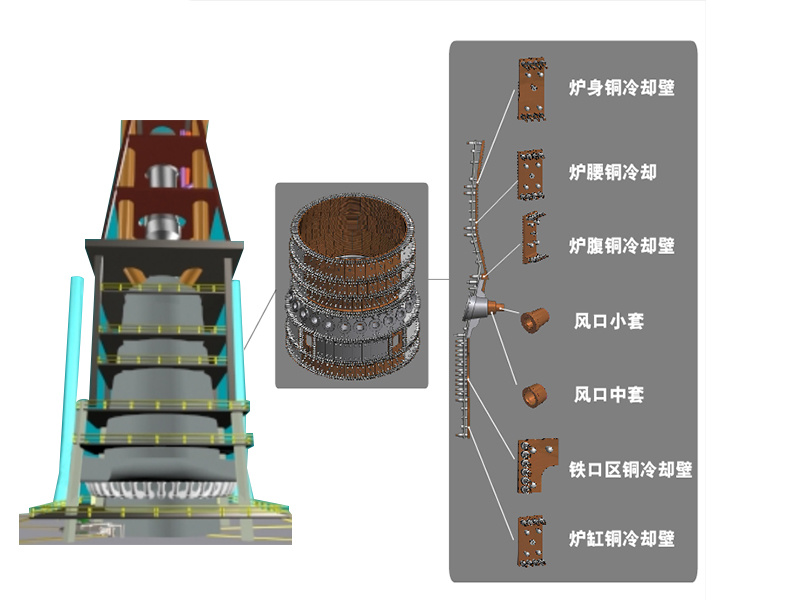

Product description of blast furnace copper cooling wall

The copper cooling wall of the blast furnace is a key internal cooling component in modern blast furnaces, especially in high-heat-load areas such as the furnace belly, furnace waist and the lower part of the furnace body. Its core function is to help the blast furnace form and maintain a stable "slag skin" at these key parts through its efficient heat conduction performance, thereby protecting the furnace structure and providing support for the long-term stable operation of the blast furnace.

I. Core Features

High thermal conductivity

The thermal conductivity of copper is more than ten times that of cast iron, which enables the copper cooling wall to quickly conduct away heat and promote the stable adhesion of slag skin on the hot surface. Even if the slag skin falls off due to fluctuations in working conditions, it can be regenerated within a relatively short period of time (about 20 to 30 minutes), while traditional cast iron cooling walls take several hours.

Thermal shock resistance and thermal shock resistance

The high elongation and uniform temperature distribution of copper material enable it to withstand intense thermal cycles. It can withstand a relatively high heat flux intensity impact in the short term (for example, 30 minutes), avoiding cracking caused by sudden temperature changes.

Structural strength and life design

Through the deep hole processing of rolled copper plates or the casting process of embedded pipes, the water channels inside the cooling wall are closely combined with the main body, reducing thermal resistance. Reasonable control of the length of the cooling wall (generally recommended not to exceed a certain range, such as 4 meters) can effectively suppress the accumulation of long-term thermal deformation and support the blast furnace to achieve a longer service life.

Ii. Common Process Types

Type |

Process characteristics |

Applicable scenarios |

|---|---|---|

| Rolled copper plate drilling cooling wall | High-purity oxygen-free copper plates (Cu≥99.95%) are used. The cooling water channels are processed through deep hole drilling and then welded into shape. Dense structure, short heat conduction path, and no gap thermal resistance. | The high heat load areas such as the furnace belly and waist of blast furnaces are suitable for new or overhauled blast furnaces. |

| Cast copper cooling wall | It is integrally cast through pre-embedded copper tubes or alloy tubes, allowing for the design of complex waterway shapes. The cost is relatively low and it is suitable for areas with special structures. | Non-standard areas such as iron openings and air vents, or projects that are sensitive to costs. |

| Copper-steel composite cooling wall | Combining the thermal conductivity of copper and the mechanical strength of steel, explosive composite welding technology is adopted. It has high mechanical strength, low installation requirements and certain advantages in production cost. | Special working conditions such as vanadium-titanium magnetite smelting, or scenarios where cost and performance need to be balanced. |

Iii. Application Guidance

Applicable parts: Mainly deployed on the belly, waist and lower part of the furnace body of blast furnaces. These areas have high heat loads and severe charge erosion and chemical erosion.

Key points for installation and maintenance

When installing, it is necessary to ensure that there is an appropriate gap between the inlet and outlet water pipes and the furnace shell to avoid alternating stress on the welds due to thermal expansion and contraction.

It is recommended to be equipped with a soft water closed-loop circulation cooling system to prevent water channel scaling and establish an online monitoring mechanism for temperature and flow.

Economic performance: Although the initial investment may be relatively high, its long service life and stability help reduce unplanned shutdowns. From a full life cycle perspective, it may lower maintenance costs.

Iv. Customization and Service

According to the blast furnace type, operation system and assembly conditions of specific areas (such as iron mouth and air inlet), non-standard designs can be provided, including size adjustment, optimization of water channel layout and customization of brick inlaying structure. Support technical collaboration based on the parameters provided by the customer.