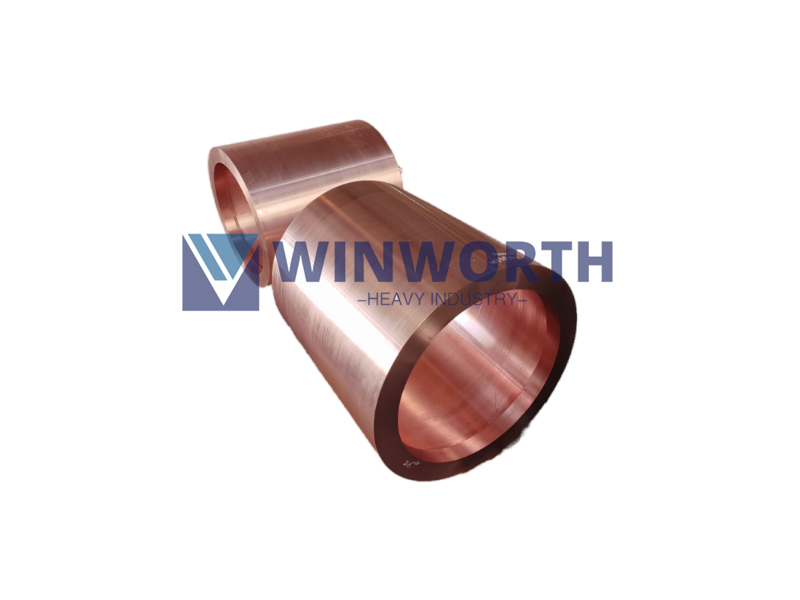

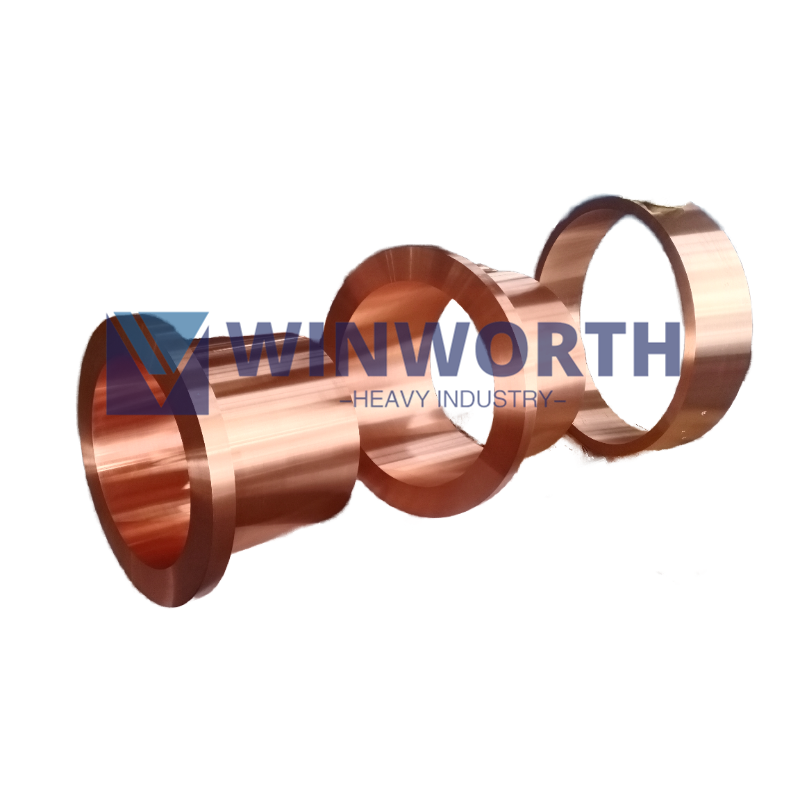

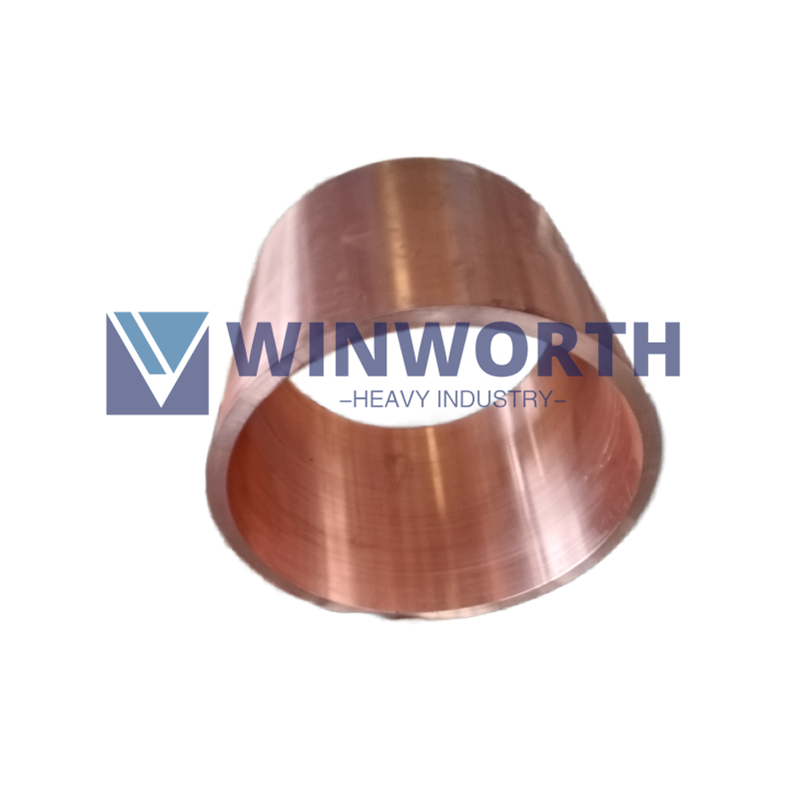

Product Name: CuCrZr Copper Sleeve / Chromium Zirconium Copper Bushing

Product Overview

A CuCrZr copper sleeve is a cylindrical component machined from chromium zirconium copper alloy, designed to serve as a critical sliding bearing, connecting element, or electrode holder in high-stress industrial environments. It combines excellent electrical and thermal conductivity with high mechanical strength, making it ideal for applications involving heavy loads, elevated temperatures, and frequent thermal cycling, such as resistance welding, heavy machinery, and continuous casting systems .

Key Features & Advantages

Feature | Technical Benefit |

|---|---|

| High Electrical Conductivity | Conductivity ≥75% IACS (≥43 MS/m), ensuring efficient energy transfer in welding and electrical applications . |

| Exceptional Hardness & Wear Resistance | Hardness ≥78 HRB (≥137 HB); maintains structural integrity under abrasive conditions . |

| High Softening Temperature | Withstands temperatures up to 550°C without significant loss of hardness, suitable for prolonged high-temperature operations . |

| Good Corrosion & Oxidation Resistance | Performs reliably in atmospheric, freshwater, and mild chemical environments . |

| Customizable Fabrication | Available as sleeves, bushings, rods, or plates; supports tailored dimensions, tolerances, and surface treatments . |

Technical Specifications

Material Composition (weight %):

Cr: 0.1–0.8%, Zr: 0.08–0.6%, Cu: Balance .

Physical Properties:

Density: ~8.9 g/cm³; Tensile Strength: ≥380 MPa; Elongation: ≥15% .

Thermal Conductivity: ~330 W/m·K, enabling efficient heat dissipation .

Standards Compliance: RWMA Class 2/3 (comparable); ISO 9001 certified manufacturing .

Primary Applications

Resistance Welding Electrodes

Used as electrode holders, shafts, or bushings in spot/seam welding machines for automotive and appliance manufacturing .

Heavy Machinery Components

Bushings, bearings, and sliding parts in crushers, extruders, and mining equipment due to high wear resistance .

Continuous Casting Systems

Sleeves for casting rolls in non-ferrous metal processing (e.g., aluminum strips), withstanding thermal cycling and roll pressures .

Electrical Conductivity Parts

Switch contacts, connectors, and conductive nozzles in electrical systems .

Customization & Services

Size Flexibility: Custom inner/outer diameters, lengths, and thicknesses based on drawings .

Forming Options: Rods, plates, or forged blanks; surface treatments (e.g., anti-oxidation coatings) available.

Quality Assurance: Provided with material certifications (chemical composition, hardness, conductivity tests) .

Why Choose CuCrZr Sleeves?

CuCrZr sleeves offer a balance of high conductivity, thermal stability, and mechanical durability, reducing downtime and replacement costs in demanding applications. Their performance is further enhanced through age-hardening treatments, ensuring longevity in extreme operational conditions .

For detailed technical drawings or specific requirements, feel free to share your project parameters for tailored solutions.