Chromium zirconium copper (CrZrCu

#Industry News ·2022-09-02 11:40:58

Chromium-zirconium copper is an alloy copper made by precipitation strengthening with copper (Cu) as the base, adding chromium (Cr), zirconium (Zr) and other trace elements. It has excellent electrical conductivity, thermal conductivity, crack resistance, high hardness, strong high-temperature resistance, high softening temperature, and is wear-resistant and explosion-proof.

Chromium-zirconium copper is widely used in the preparation of resistance welding electrodes, inner linings of molds for continuous casting machines, lead frames for integrated circuits, overhead conductors for trams and electric locomotives, contact materials, small sleeves of air inlets for blast furnaces in ironmaking, rotor end rings, excitation tracks, roller electrodes, electrodes for spot welding machines, welding pliers, electrode grippers for flash butt welding systems, parts of acceleration systems under high electrical and thermal stress, and gray cast iron Ingot molds for iron and cast steel, casting wheels and continuous casting molds, plastic molds, commutator vanes for motor commutators, etc. It involves multiple industries such as automobiles, high-speed rail, aerospace, and industrial robots.

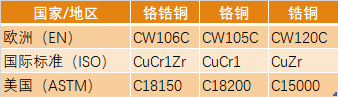

Common material grades

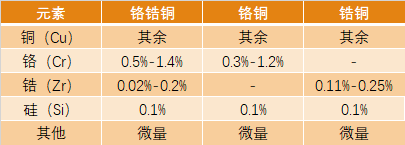

Chemical composition (mass fraction) * :

It can be appropriately adjusted according to customer requirements

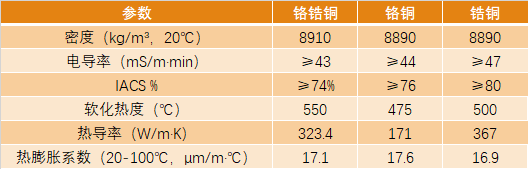

Physical properties

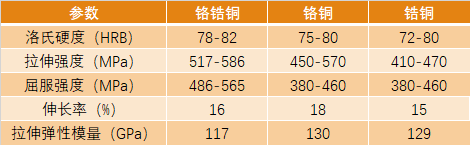

Mechanical properties

Mechanical properties are related to the shape of the product and the heat treatment method.

Typical applications

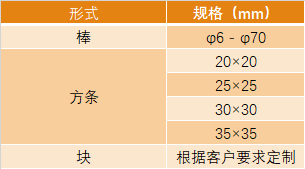

Common specifications

The form and specification of each product can be customized according to customer requirements and are not limited to the specification range shown in the above table.

Product quality assurance: Quality inspection standards

• JB/T 7598-2008 Copper-chromium-zirconium alloy for Resistance Welding electrodes

• GB/T 230.1 Test Method for Rockwell Hardness of Metals

• GB/T 3048.2 Test Methods for electrical Properties of wires and cables - Resistivity test for Metallic Conductor materials

• GBT 33945-2017 Chromium-zirconium copper rods for commutator segments of motor commutators

• Refer to international standards

If necessary, other quality standards can also be adopted. For specific details, please inquire.

Product quality assurance: Quality inspection methods

The conductivity of the finished product is measured by using a digital display eddy current conductivity meter.

Measure the hardness of the finished product with a vertical fully automatic Rockwell hardness tester;

• Use advanced spectrometers to test the content of each component of chromium-zirconium-copper;

• Non-destructive testing of finished products for internal defects using ultrasonic flaw detectors;

Digital inspection instruments can significantly reduce random errors caused by manual measurement and reading, providing more accurate data and stricter quality control.